Explore the pivotal role of forecasting in inventory management. Dive into its benefits, challenges, and best practices to optimize stock levels, reduce costs, and boost customer satisfaction.

RF Plus™ for Infor VISUAL ERP is a warehouse management software that equips manufacturers with everything they need to increase throughput and optimize warehouse efficiency.

Our team has been working in the supply chain industry for more than two decades. We understand manufacturing and the needs of our manufacturers, so our products and services reflect that knowledge and experience.

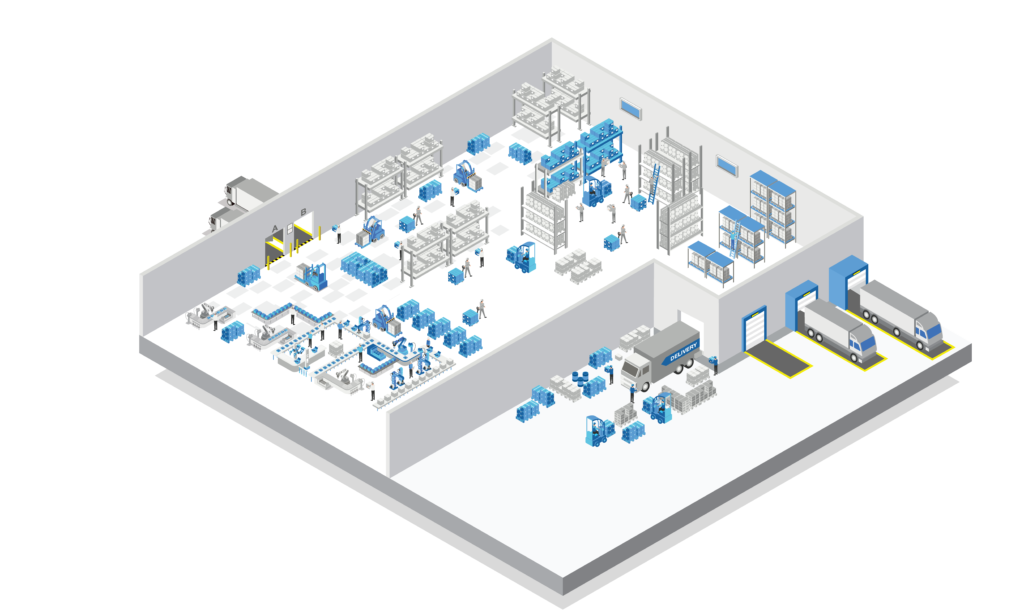

RF Plus offers four modules – Inventory, Inbound, Production, and Outbound – to capture warehouse data. These modules facilitate inventory tracking and prevent material loss, ensuring efficient manufacturing processes.

Warehouse Automation for everyone

The Smart Warehouse™

A curated group of complementary technologies that work in tandem with your ERP or WMS, and addresses the blind spots and limitations of traditional methods, such as barcoding and wireless technologies.

Our innovative solution empowers companies to enhance productivity, optimize performance, and stay ahead of the competition.

Experience the future of warehouse management.

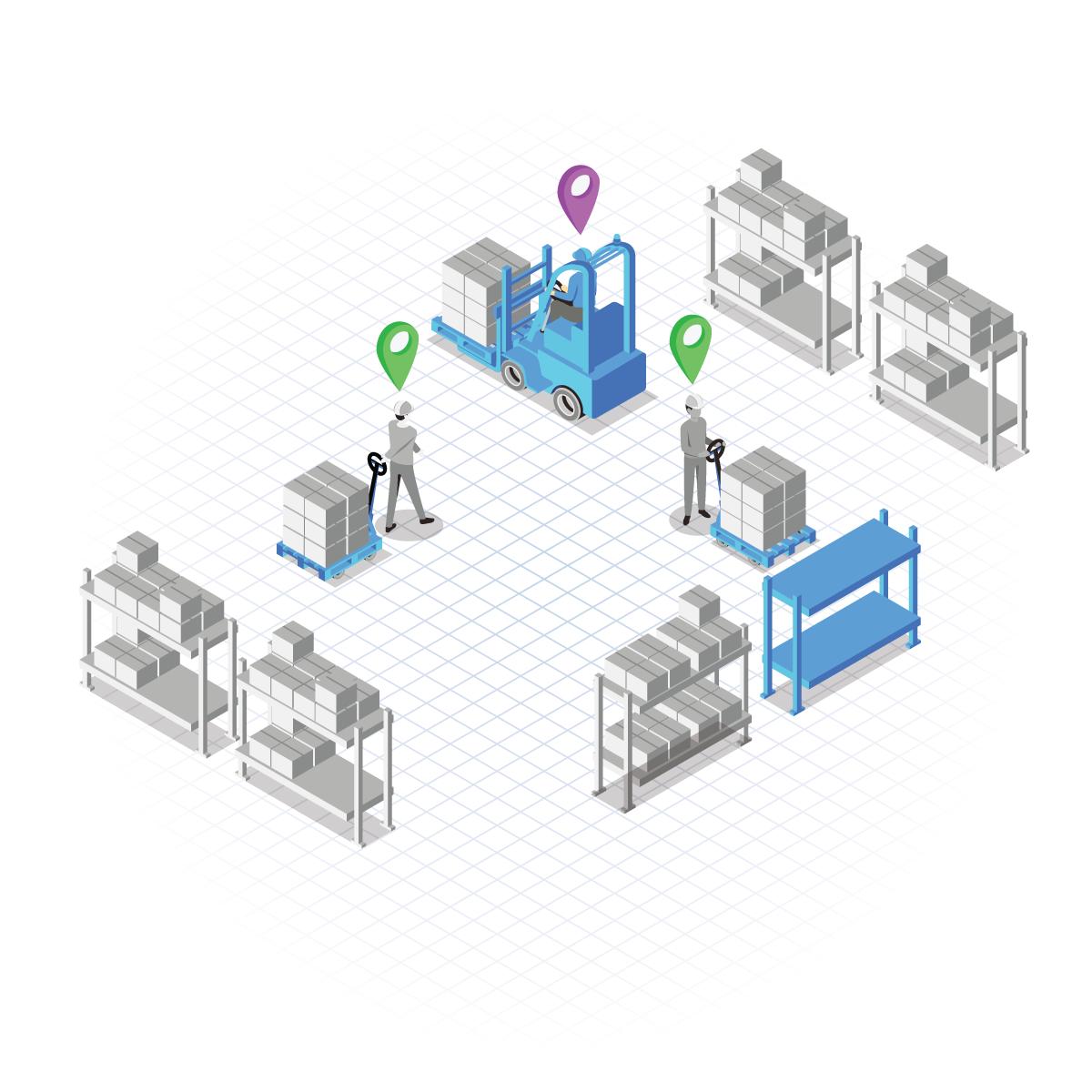

Maximize efficiency, visibility & control with TED’s warehouse task management software

TED™ guides, directs & optimizes workflows

Achieve complete visibility and control of your labor, equipment and assets, leading to a new era in productivity and throughput.

Navigate the future of warehouse management, automation, and inventory management. Explore our free resources featuring insider tips, expert insights, industry trends and more!

By providing the information, you agree to Portable Intelligence’s Privacy Policy

Address

Head Office:

Portable Intelligence Inc.

7181 Woodbine Avenue, Suite 223

Markham, ON L3R 1A3

R&D Lab:

Portable Intelligence Inc.

ventureLAB Innovation Space – Markham

Convergence Centre Suite/Atrium

#3600 Steeles Ave. E, Markham, ON L3R 9Z7

©2023 Portable Intelligence.

A new era in warehouse productivity and smart warehouse management systems. Privacy Policy